Marvels of nature to be appreciated and not to be abused Dr. Mae-Wan Ho

Spiders are beautiful, graceful creatures, and their silk with which they construct their webs, egg cases, immobilize their prey, etc., is indeed among the marvels of the living world.

I have always loved spiders and cannot understand arachnophobia (fear of spiders), an extreme form of which I witnessed in my own mother. If ever she spotted one in the house, she would screech and run for help, remaining agitated until the object of fear was unceremoniously squashed and its crumpled body flung out of sight.

I, on the other hand, would spend hours watching the creature if I catch sight of one; just as surely as it must be watching me.

There was a spider in my garden one summer a few years ago, which suspended itself upside down in front of my window, in the centre of its huge web some metres in diameter. There we could scrutinize each other to our hearts’ content as I sat at my desk trying to work on my computer. It was in the identical position for two successive summers, and I could almost swear it was the very same spider.

In 2004, British art historian Simon Peers and American fashion designer Nicholas Godley joined forces to create a tapestry from the brilliant golden silk of the Madagascar spiders then on display at the Madagascar National Zoo. The impressive size of Nephila spiders makes it relatively easy to extract their silk and because they are used to building large, densely-woven webs, they can produce over 300 metres at a time [1]. Peers and Godley gathered and silked more than a million spiders for the project, by enlisting helpers to fix the dangling dragline of the spider to a spool to draw out the hundreds of yards of silk that the spider had stored up in its silk gland. Afterwards, the exhausted spider was released back into the wild to replenish its reserves, and could be silked again in a week or so. The resulting tapestry went on display at the American Museum of Natural History in the fall of 2009. It has been on show at the Victoria and Albert Museum in London since January 2012, with an additional golden silk robe [2].

It is stunning. The fabric is a rich burnished gold, light as a whisper yet tenaciously strong. The intricate, geometric design of the silk tapestry representing birds and flowers is based on traditional textile originally reserved for the Madagascan royalty. The robe is a brocade embroidered with a more representational design of spiders and flowers; truly a work of art belonging as much to the golden orb spiders as to the human artists and artisans who participated in creating it.

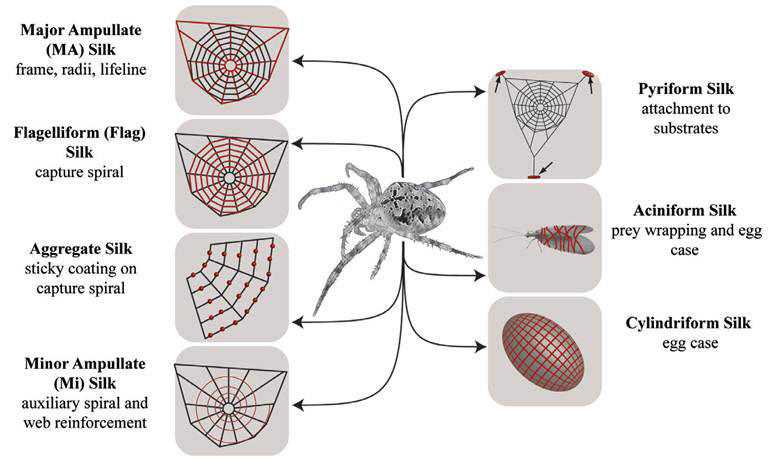

Human beings have used silks produced by a large variety of arthropods for thousands of years. The silk from Bombyx mori has been obtained from the farmed silkworms in China for at least 5 000 years. Spiders cannot be farmed, apparently due to their aggressive nature and cannibalistic tendencies, but the webs of orb weaving spiders (Araneidae) have been used historically for fishing and wound dressing, thanks to their astounding mechanical and biomedical properties [3]. There are many kinds of spider silks. A female orb weaving spider is able to produce 7 different silks, including one for egg cases (see Figure 1).

Figure 1 The seven kinds of silks produced by the orb weaving female spider (highlighted in red) from Eisoldt, Smith and Scheibel [3]

Spider silks are tailored for different purposes, and have different mechanical properties. The stress required to break the fibre ranges from 0.02 to 1.7 GPa, while the extensibility varies between 10 and 500 %. (Stress or tensile strength is measured as force per unit area in Giga (109) Pascals; a Pascal is 1 Newton (1 kg metre/s2) per square metre.) In comparison, steel breaks at 1.5 GPa, and is hardly extensible. Most spider silks have a combination of strength and extensibility which yields a very high toughness - the amount of energy absorbed per volume before breakage - that exceeds most natural or man-made fibres, making it ideal for bulletproof vests. Also common for all silks is the viscoelastic behaviour, as upon stretching, energy is dissipated in the form of heat, diminishing any elastic recoil.

The most thoroughly investigated silk is the dragline silk, the lifeline that a spider drags behind, produced in the major ampullate silk gland, hence referred to as major ampullate silk. It is used for the frame and radii of an orb web, and has a maximum strength of up to 1.7 GPa. Although Keviar carbon fibres have a higher strength and stiffness, spider silk fibres have a much higher toughness due to their greater extensibility. It is the dragline silk of the Golden Orb spider that has been silked for making the gold robe on show. The dragline silk also has other interesting features.

For example, a hanging spider hardly ever twists. When a dragline thread is twisted, it does not oscillate around the new position like a Keviar fibre would. Instead, the fibre slowly returns to its initial position, indicating that there is a shape memory in the thread. Another interesting feature is its ability to super-contract on wetting, or when the relative humidity is above 60 %. The silk thread swells in diameter and shrinks in length by about 50 %. (There must be an application for moisture sensing and humidity control here.)

All spider silks are mainly composed of one or more proteins called spidroins, which tend to be large, up to 350 kDa. They share a common primary structure comprising a large central core of repeated modular units, accounting for 90 % of the amino acids of the protein, flanked by non-repetitive domains of approximately 100 -140 amino acids. The terminal sequences, highly conserved throughout spider species and silk types, are essential both for the storage of spidroins in the silk glands and for fibre formation in the spinning duct, where they trigger crucial steps in the complex assembly of the spidroins as the result of changes in pH or ionic composition and strength.

The sequence of the repetitive core is tailored for the individual mechanical functions of the different silks. In general, it consists of modular units each with about 40 – 200 amino acids, and the units are repeated up to approximately 100 times within the core domain. In the major ampullate, minor ampullate and flagelliform silk, the modular units are mainly comprised of a subset of the sequence motifs: (A)4-14.(GA)n.(GGX)n and (GPGXX)n, where A is alanine, G is glycine, P is proline, and X is a variety of different amino acids. In contrast to the termini, the core region is intrinsically unfolded, as long as the spidroins are stored in the gland.

The major ampullate spindroins are MaSp1, which has the core modular structure (A)4-14.(GGX)n and MaSp2, with the core modular structure (A)4-14.(GPGXX)n.

Dragline fibres, silked from spiders, have been examined under the electron, atomic force and light micrsoc0pes, revealing a core-shell structure. The shell is quite thin and contains lipids, glycoproteins and other silk proteins. The core consists mainly of the two spidroin proteins MaSp1 and 2. A single MaSp1 module usually consists of a polyalanine block and several GGX motifs. In modules of MaSp2 the GGX motif is replaced by GPGXX. Several dozens of repeats of modular units build the complete core region of these spidroins. The polyalanine block forms defined nanosized crystals (2 x 5 x7 nm) based on tightly packed antiparallel b-sheets, in which polyalanine stretches from different silk molecules often form non-covalent crosslinks. GGX may form b-sheets as well as less ordered helical structures. The GPGXX motif forms b-turns, which, when repeated yield a spiral structure similar to elastin.

All the secondary structures are due to hydrogen bonds (special bonds consisting of a hydrogen shared between two electronegative atoms, such as oxygen and nitrogen). It is the richness of hydrogen bonds in natural spider silk that gives it all the distinctive mechanical properties, and in addition, enables the silk to self-heal after being stretched, by reforming these hydrogen bonds [1].

In Araneus diadematus, the two silk proteins named fibroins - ADF3 and ADF4 – have the core structures (A)4-14.(GGX)n (GPGXX)n and (A)4-14. (GPGXX)n respectively. It appears important to have a pair of hydrophobic and hydrophilic spidroins: MaSp1/ADF4 are more hydrophobic and MaSp2/ADF3 more hydrophilic [3].

The primary structure of the silk protein alone does not explain the outstanding properties of dragline silk fibre. Fibres technically spun from reconstituted spidroins (chemically dissolved spider silk fibres) or from the original spinning dope taken from the silk gland show completely different mechanical properties compared to fibres spun by spiders. The natural process in the spider involves pre-aligned flow of a nematic (thread-like) liquid crystal solution with 50 % water, elongation through a narrowing S-shaped duct, and a pulling of the fibre out of the spigot, leading to some structural changes and phase separation between the water solvent, which is actively removed by the epithelial cells, and the spidroins. As well as mechanical influences, chemical changes occur especially in the spider’s S-shaped duct. There, the exchange of sodium and chloride ions for potassium and phosphate ions is responsible for exposing the hydrophobic areas within the C-terminal non-repetitive domain. On lowering the pH from 7 to 6, the amino terminal domains dimerize (join up in pairs), acting as additional crosslinks between the spidroins.

Once the fibre has left the spider, the spider pulls and stretches the fibre leading to further water evaporation and additional alignment of the molecules inside the fibre.

Fibrils oriented along the fibre axis form the core of the fibre, resembling the structure of a rope. Small crystallites (2 x 5 x7 nm) comprising tightly packed alanine b-sheets and larger crystalline regions (> 100 nm) based on glycine-alanine sequences with high b-sheet content can be found. Both crystalline regions are interconnected by an ‘amorphous’ matrix with loosely arranged helical structures oriented along the fibre axis. The crystalline areas are responsible for strength while the matrix is responsible for elasticity.

Apart from fibres, which have numerous applications in light-weight textiles for military and civilian use as well as in fashion design; spider silk can also self-assemble into non-natural shapes such as spheres, capsules, films, and hydrogels, with numerous potential applications, as carriers for drugs, scaffolds for tissue engineering, cosmetics, and even electronic and biosensing devices [3]. Much effort is currently dedicated to genetic engineering spider silk for commercial production. But it is important to do so ethically, without undue exploitation of animals (see [4] Unspinning the Web of Spider-Goat, SiS 54), and with due regard for safety [5] (Genetic Engineering Spider Silk, SiS 54).

Article first published 05/03/12

Comments are now closed for this article

There are 3 comments on this article.

Rory Short Comment left 6th March 2012 01:01:52

Nature has been developing/evolving solutions for problems for billions of years. Sad to say to this day 'Johnny come lately' humankind arrogantly thinks that somehow it knows better than nature its parent.

MP Nougaret Comment left 6th March 2012 01:01:42

yes zoologists and farmers in Montpellier tried to raise spiders for silk last century, by the Lez river, but they do eat it each other and it failed

Love to watch them too

MP

Todd Millions Comment left 8th March 2012 09:09:13

I recall reading in an 1950s encyclopidia annual,that one of the reasons ww2 americian bombsights were superior was,one widow in Newhampshire sending samples of-"milked spiders"silk too the war department.The pet spiders were in an attached greenhouse collected by her late husband.They were so used too human handling that she just had too tickle them with a glass rod and they began too produce silk that she could wind up onto wire bobbins.

This silk produced finer crosshairs than any other available line.The next best being blond human hair.

Strange too think that 'A'retentive german housefraus did there part too 'squash'hitlers chances eh.

Since I was a child,any spider I find in the house,is grabbed by silk or taken in hand and set outside.This struck my grandfather who began too do the same.Later I had a room set with small ground crawling leaping spiders.They keep the room free of blackflies.So I was loath too remove them,but they liked too hide in my bed.We came too an arrangment.I tapped the bed frame before getting in it,and they scurried up the wall it was against.So -no conflict.